The stamping manipulator is driven by the servo system, the manipulator moves left and right, and the stepping mechanism drives the manipulator to move up and down. The whole system is under the central control of the PLC system and is connected with the punch to realize automatic stamping. Different punching machines, different dies and different stamping processes have different solutions of stamping automation equipment and different automatic production efficiency. Generally, the automatic stamping efficiency is 15-25 times per minute. Compared with the single efficiency of personnel operation, the stamping manipulator does not seem to have the advantage of efficiency. However, based on eight hours a day, because the stamping manipulator will not be fatigued and have no emotions, it can continue to produce, while it is difficult for manpower to maintain the same efficiency and continue to work continuously due to physical, emotional and other factors. In addition, when the stamping manipulator is automatically produced, the potential risk of industrial accidents caused by personnel operations is avoided.

The manipulator can automatically complete several prescribed actions according to the preselected program to realize the automatic clamping and transportation of objects. In stamping production, it is not only used to complete the loading and unloading work on one press to realize single-machine automation, but also can be used in a flow production line composed of several presses to realize automatic transfer of workpieces between presses, forming automatic Stamping line. Since the manipulator can easily change the working procedure, it is more important for the realization of production automation in the stamping production of small and medium-sized parts that frequently change product varieties.

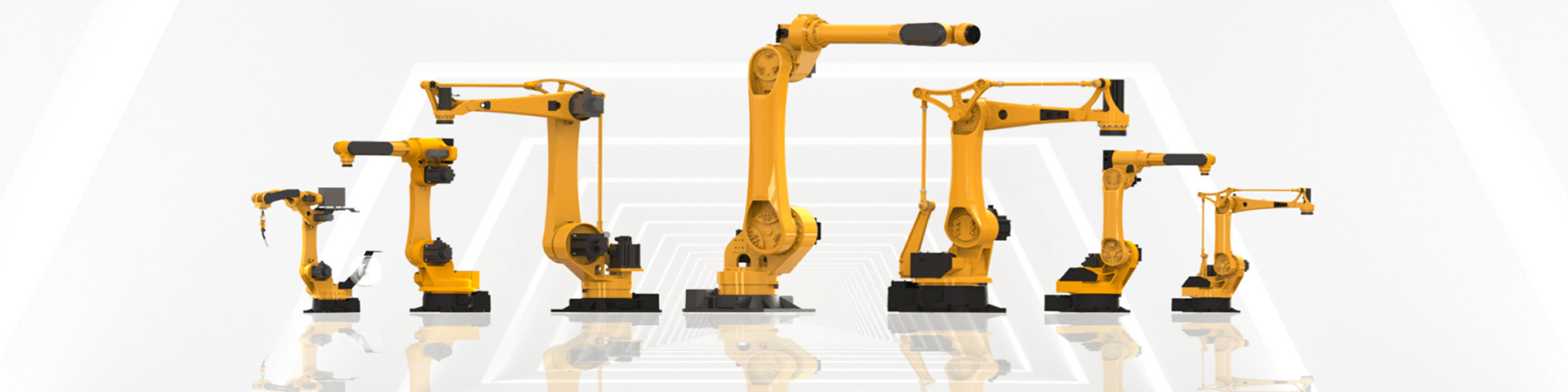

The following is an introduction to the composition of the stamping manipulator

1. The mechanism of the stamping manipulator composed of the main machine and the auxiliary machine;

2. The connecting rods are installed on the main and auxiliary machines, and the length of the connecting rods is determined according to the number and specifications of the punches;

3. A mechanical arm is installed on the connecting rod, and the products are sucked/clamped by suction cups, electromagnets, and manipulator clips;

4. The main machine of the stamping manipulator is driven by the servo system, the X axis moves left and right, and the Z axis moves up and down;

5. The stamping manipulator is centrally controlled by PLC, and the touch screen can debug parameters.

Scan WeChat

Scan WeChat