A must-see in the manufacturing industry: understand the palletizer in one article

With the increase of labor costs and the increase of production volume of enterprises, it has become an inevitable trend that heavy physical and repetitive labor is replaced by machinery. Especially in some chemical industries with high risk factors, the working environment is relatively harsh, and occupational diseases affect people’s health. Good health, and replacing labor with machinery in harsh working environments can greatly enhance production safety.

From the economic point of view: a fully automatic palletizer can replace six workers. Realize intelligent operation management, 7 × 24 hours of uninterrupted operation, which can greatly reduce labor and labor intensity.

What is a palletizing robot?

The palletizer is to put the product packaging that has been put into the container on the pallets and pallets (wood, plastic) in a certain arrangement, and perform automatic stacking. Realize intelligent operation management, which is simple and easy to master. It can greatly reduce the labor force and reduce labor intensity. Palletizer is a device that automatically stacks the bags, cartons or other packaging materials conveyed by the conveyor into stacks according to the working method required by the customer’s process, and transports the stacked materials.

The automatic palletizer is a high-tech product integrating machine and electricity. The medium and low-level palletizer can meet the production needs of medium and low output. According to the required grouping method and number of layers, it can complete the stacking of various products such as material bags, plastic blocks and boxes. The optimized design makes the stack shape tight and neat.

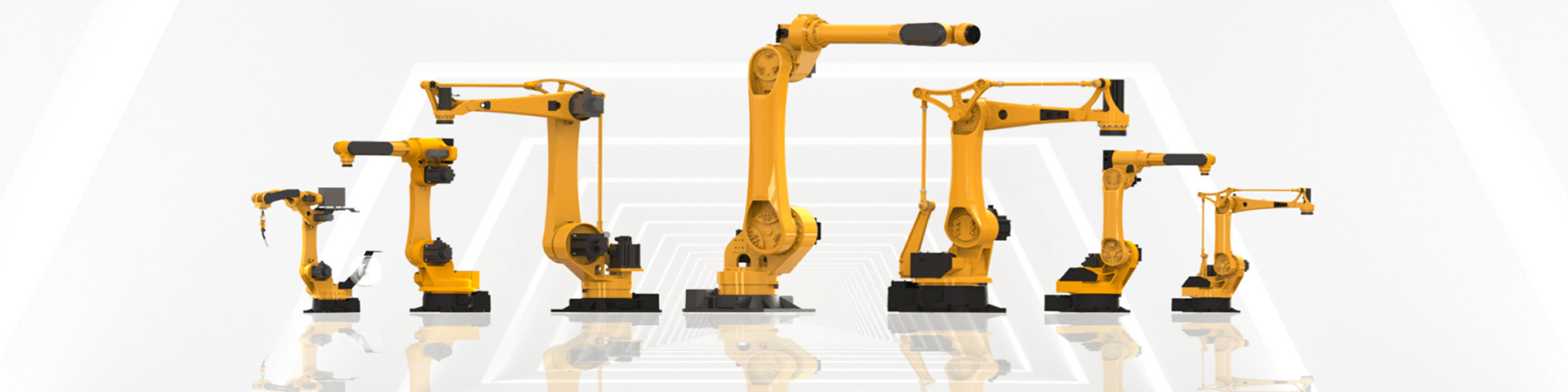

Classification of palletizing robots

Palletizers can be divided into : palletizing robots (also known as “manipulator palletizers”), high-position palletizers, coordinate palletizers, and column-type palletizers.

Palletizers are high-tech electromechanical products with a wide variety of types, mainly used for handling, palletizing, depalletizing and other operational tasks of workpieces or products. According to the industry, automatic palletizers are divided into: food and beverage industry palletizers, cement automatic loading palletizers, industrial product palletizers, etc.

Palletizing robot (manipulator palletizer)

It is a mechanical arm type equipment, the palletizing efficiency can reach 800 packs per hour, the whole machine is controlled by a computer, and the program is advanced, which can realize the automatic control of products. It has large mobile and flexible loads and is suitable for large and medium-sized enterprises.

High-position palletizer

It is a kind of palletizer with high retention rate in the market, with high palletizing efficiency, about 450 packages per hour. The price is low, the structure is stable, the procedure is simple, the operation is convenient and easy to use, and the palletizing forms are various.

Coordinate palletizer

It adopts the four-axis action mode of the robot, which has a small footprint, high palletizing efficiency, simple installation and flexibility. The price is low, but the load is small, and the supporting facilities are not easy to install.

Column Palletizer

Using four-axis or five-axis action, the bottom slewing bearing can realize 270° rotation of the upper mechanical arm, using the robot palletizing program, combining the advantages of the palletizing robot and the coordinate palletizer, it can meet the palletizing of 2~3 production lines at the same time. stacking needs.

What are the advantages of palletizing robots?

The palletizing robot has a simple structure, few parts, and greatly reduces the probability of component failure. It has reliable performance, simple maintenance and repair, and requires less inventory parts.

Small footprint. It is beneficial to the layout of the production line in the customer’s workshop, and a larger warehouse area can be reserved. The palletizing robot can be set up in a narrow space and can be used effectively.

Low energy consumption. Usually the power of the mechanical palletizer is about 26KW, while the power of the palletizing robot is about 5KW. Greatly reduces the customer’s operating costs.

Strong applicability. When the size, volume, shape of the customer’s product and the external dimensions of the tray change, it only needs to be slightly modified on the touch screen, which will not affect the normal production of the customer.

It is necessary to locate the starting point and placement point, and the teaching method is simple and easy to understand. It can be operated on the control cabinet screen and is easy to use.

Scan WeChat

Scan WeChat