Aluminum Alloy Flat Panel Welding Robot Design Scheme

1. Basic information of the workpiece

The name and drawing number of the workpiece: aluminum alloy ship board jigsaw

Workpiece size specification: length X width X height, 8000X1600X6 four pieces spliced

Material of workpiece: aluminum alloy; thickness 6mm

Workpiece weight: about 1000 Kg

2. Workpiece welding requirements:

The appearance of the welded parts is beautiful, and the double-sided welds are fully melted.

3. Schematic diagram of the workpiece cross-section

Welding process and requirements of automatic welding on workpieces to be welded

1. Welding process

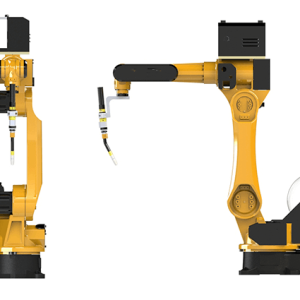

Welding method: MIG gas shielded welding;

Protection method and wire diameter: shielding gas: Ar wire Ф 1.2;

Welding method: automatic welding;

Workpiece loading and unloading method: manual loading and unloading.

2. The requirements of automatic welding for the workpiece to be welded:

The surface of the workpiece to be welded shall not have oil rust and moisture that affect the welding quality;

The workpiece to be welded shall not have burrs that affect the positioning;

The error between the shape of the workpiece to be welded and the weld seam is ≤±0.5mm;

The gap between the workpieces to be welded is ≤ ± 0.5mm.

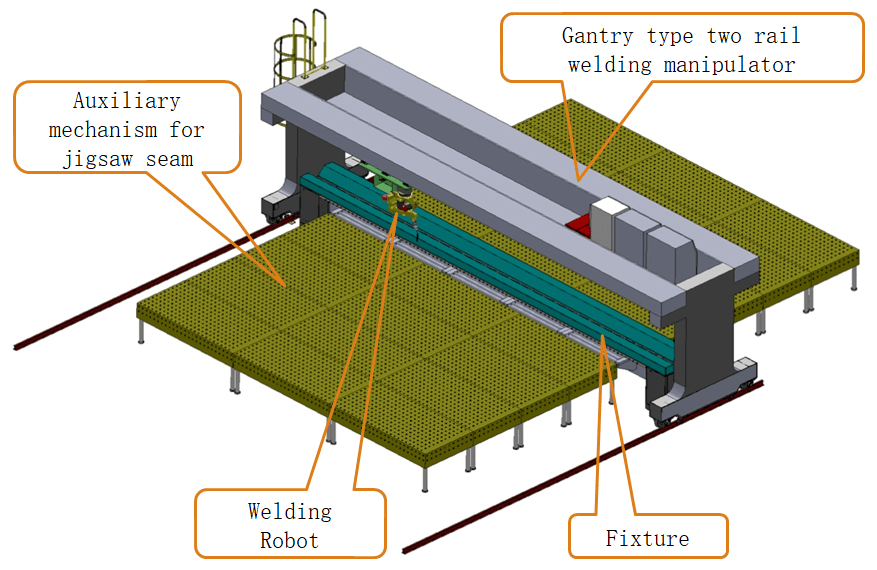

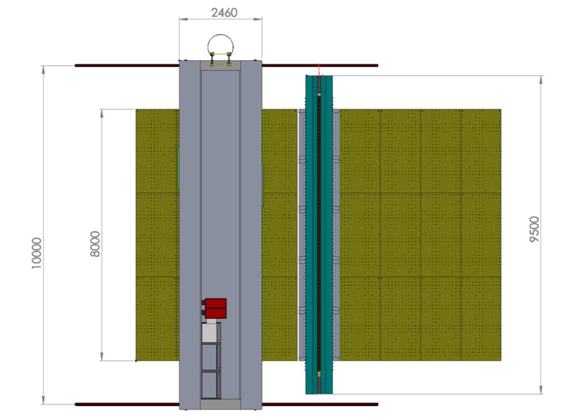

Overall layout and 3D schematic diagram of the scheme

1. Overall layout of the scheme

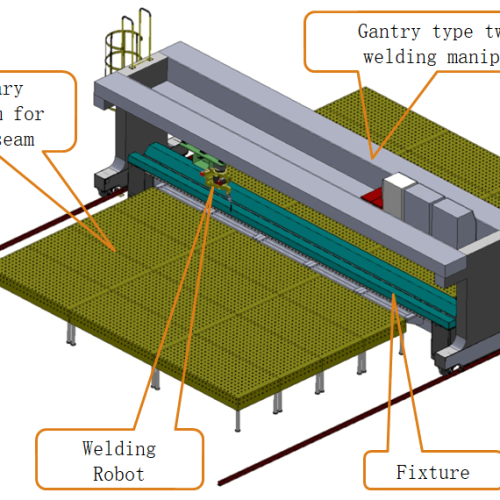

2. Overall overview of the program

Equipment name: aluminum alloy long plate seam welding workstation.

Quantity of equipment: one set.

Equipment use: It is used for seam welding of aluminum alloy medium and heavy plate workpieces. If you need to weld other similar products (within the size of this equipment), you need to replace the fixture as a whole.

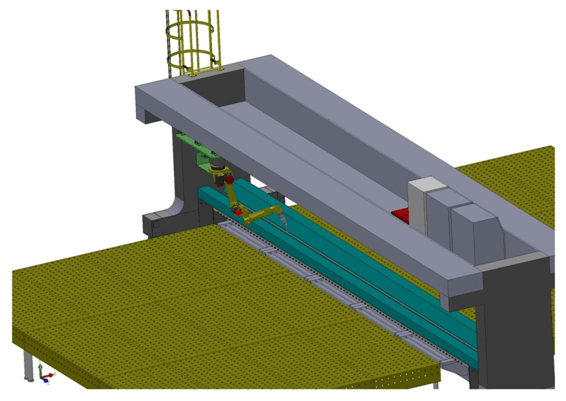

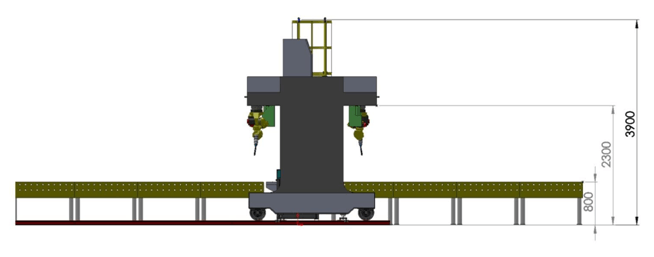

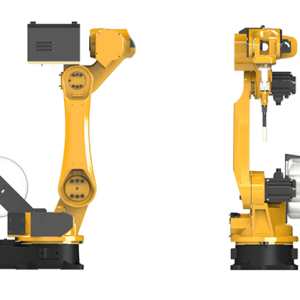

Workstation consists of one set of gantry-type aerial two-track welding manipulator, two sets of Cloos welding power source, one large-size panel jig, two sets of welding robot welding systems, two sets of laser real-time trackers, and two sets of panel stitching aids , a set of assembly control system, etc.

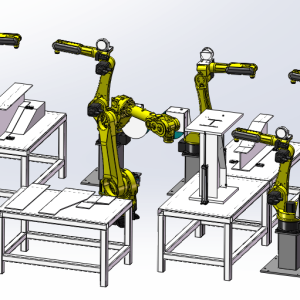

Workstation layout: The welding robot is arranged in parallel and upside down under the beam of the gantry manipulator, and is moved to the welding position through the manipulator frame of the gantry manipulator. The panel jig fixes the workpiece and aligns the seams of the workpiece, so that the gap between the welds is uniform, and the two butt plates are level and flat for welding.

Equipment operation process: Manually hoist the workpiece to the auxiliary platform corresponding to the welding fixture for seam positioning and pressing, then move the manipulator and the robot welding gun in place, and start the button box to start the manipulator for automatic welding. No manual labor is required during the automatic welding process. intervention.

3. The basic configuration table of the program

| serial number | name | model | factory | quantity |

| 1, | Welding manipulator | Non-standard | 1 set | |

| 2, | Welding Robot | FUNAC | FUNAC | 2 sets |

| 3. | welding power source | CLOOS QINTRON | CLOOS | 2 sets |

| 4. | Auxiliary mechanism for jigsaw seam | Non-standard | 2 sets | |

| 5. | Panel welding fixture | Non-standard | 1 set | |

| 6. | Integrated Control System | Non-standard | 1 set | |

| 7. | Seam tracking system | SERVO-ROBOT | SERVO | 2 sets |

| 8, | appendix | Wire feeder rack, control cabinet bracket | 1 set |

Scan WeChat

Scan WeChat